7 Stages of the Pasta Production Cycle

From Selection to Packaging: Have You Ever Wondered How Pasta Is Made?

There are seven crucial phases of the pasta production cycle: selection, grinding, kneading and kneading, drawing, drying, cooling and packaging.

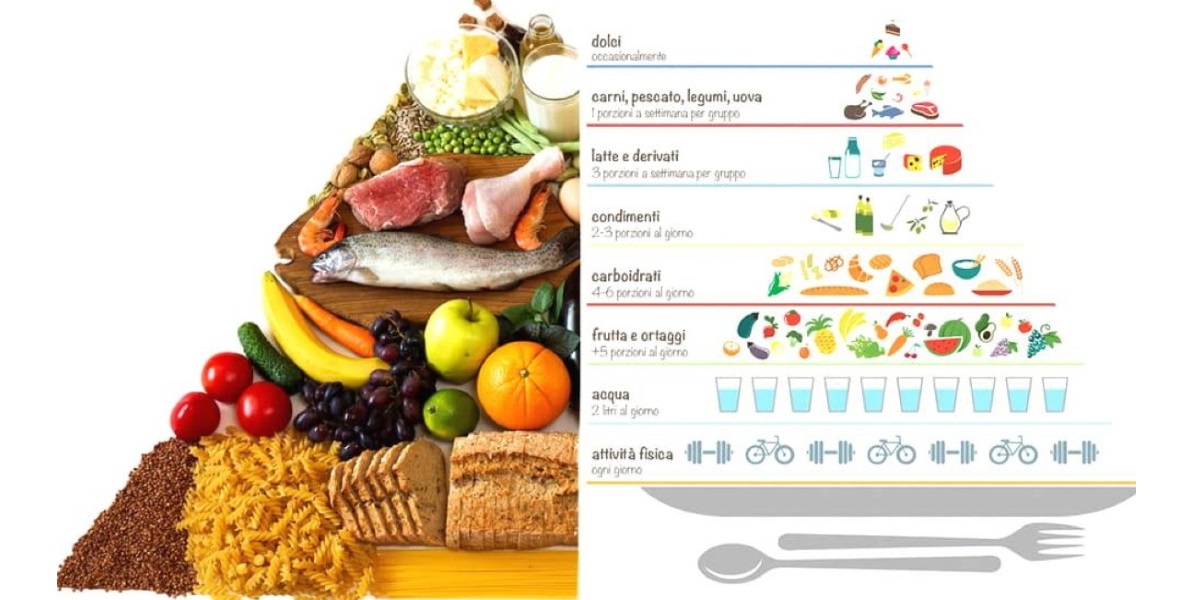

1 - Selection The selection of durum wheat semolina is a very important and very delicate phase. The semolina is selected in full compliance with the highest quality standards, which at the same time take into consideration the physical (specific weight and impurities) and technological (proteins, gluten quality and yellow index) characteristics of the raw material. For the pasta making, only the semolina obtained from the heart of the wheat grain is used, of uniform yellow color, without bran parts, with a high protein content and a quality gluten.

2 - Grinding The wheat is delivered to the mill to be sieved, cleaned of impurities and finally ground in order to obtain the best quality semolina. During the grinding process, the wheat passes through a series of rolling mills, which progressively break the wheat grains, "undress" them of the outermost layers, gradually reducing them in size. At this point the ground is passed through the sifters, which separate the bran, the small bran and the tritello. The final phase, obtained through the use of a re-mill cylinder, is aimed at refining the flours and obtaining the noble product of the grinding: semolina and granulated.

3 - Kneading and kneading The durum wheat semolina is mixed with pure water inside special kneading tanks. It is here that starch and proteins bind to water forming gluten, a protein network that binds the hydrated starch granules. The kneading, or the diameter of the particles into which the semolina is ground, affects the final invoice of the dough. A coarse kneading semolina (> 450-500 microns) enhances the technological qualities of the grain to the full, giving the dough a compact and homogeneous appearance.

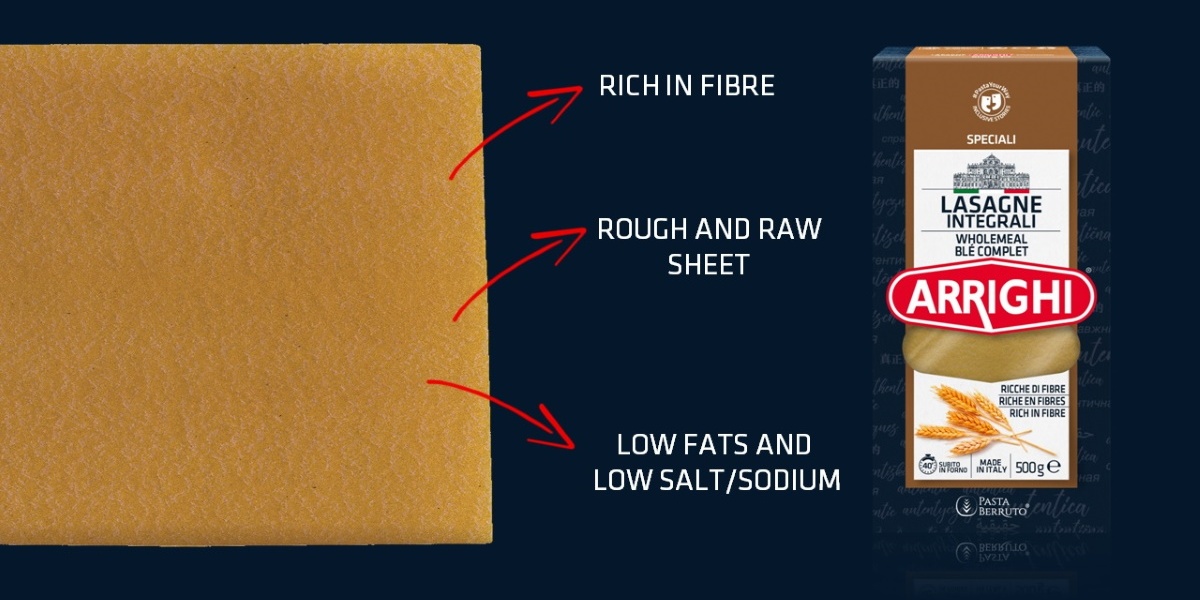

4 - Drawing In the drawing phase, the mixture obtained is then modeled by the dies, which determine the chosen shape. The pasta obtained from bronze drawing has a rough and porous surface, which allows some condiments to be retained in the best possible way, but which has the disadvantage of overcooking more easily. The finished product obtained from the Teflon drawing is, on the other hand, smoother, smoother, withstands the cooking phase better and is suitable for other types of seasoning.

5 - Drying Drying represents the most delicate moment of the entire production cycle. During this phase, the pasta is left to rest inside dryers and ventilated with hot air to reduce its water content and reach the maximum humidity limit of 12.5% ??required by law.

6 - Cooling At the end of the drying process, the pasta is cooled in special coolers. It is here that the previously ventilated pasta is brought back to room temperature.

7 - Packaging At the end of the production cycle, the pasta, stored in silos, is packaged inside cardboard boxes or transparent bags. The packaging phase fulfills the dual function of preserving the product from contamination by external agents and presenting it to the consumer accompanied by the appropriate information label.

Data source: Italian Union of Food Pastai